Toothpaste might look simple on a shelf. But the journey to getting it in a sealed, ready-to-ship tube is far from it. Once the paste is mixed and deaerated, the real challenge begins: packaging it cleanly, quickly, and without waste. This part can slow down the entire process if the equipment isn’t up to the task.

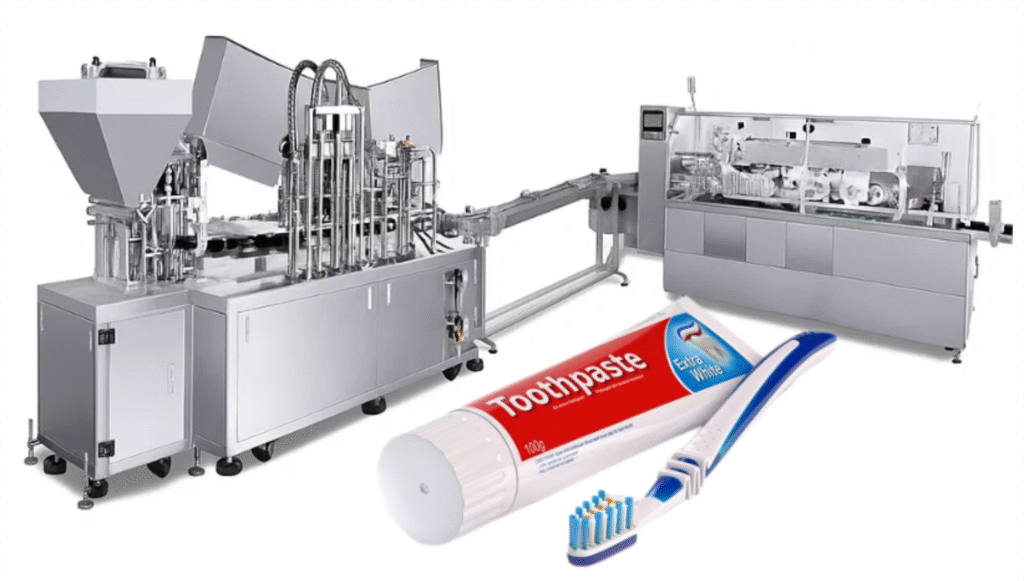

King Pack Solutions helps manufacturers get through this phase with fewer delays and greater control. Our machines are designed to deal with thick pastes, provide consistent fills, and make seals that do not fail during transit.

In this guide, we will discuss how toothpaste moves from raw paste to a finished product. We will also get into details about how advanced filling and sealing systems make that possible.

Key Stages in Manufacturing Toothpaste Before Packaging

Toothpaste manufacturing is not just a process of mixing different ingredients. It is a process where every single step is an integral part of getting the final product.

Before the tubes hit the shelves, here’s what happens behind the scenes:

- Raw materials are measured and blended to form a smooth, consistent base

- The mix goes through homogenization to break down particles and refine texture

- Each batch is tested to confirm quality and meet safety standards

Once those steps are done, it’s time for packaging. And that’s where things get serious. Filling and sealing come at the very end. But they carry the highest risk.

Thick toothpaste has to be pushed into tubes without air gaps or spills. Hygiene rules are tight, and any error can cause waste, delays, or even recalls.

This is why modern producers now rely on advanced filling and sealing machines. These systems don’t just improve speed. They protect product integrity, meet regulatory demands, and reduce rework.

Toothpaste Filling Technology: Precision and Efficiency

Toothpaste requires accuracy when filling it. It’s not liquid like water, nor entirely solid. The paste needs to be divided into tubes without air spaces and without product waste. King Pack’s piston fillers are designed for such work. They fill paste into tubes without mess or waste.

Here’s a brief overview of popular filling machine types utilized in the manufacturing of toothpaste:

| Filling Type | Best For | Filling Method | Offered by King Pack |

| Piston Filler | Thick, viscous pastes | Volume-based piston drive | ✅ Yes |

| Pump Filler | Lower-viscosity or runny pastes | Continuous flow control | ✅ Yes |

| Volumetric Filler | Consistent batches | Pre-set chamber fill | ✅ Yes |

| Weight-based Filler | Sensitive fill requirements | Real-time weight feedback | ✅ On request |

These machines provide controlled filling, cleaner operation, and higher speed output. Automatic fillers by King Pack also minimize the likelihood of contamination by reducing contact with hands.

Sealing That Locks In Product Quality

Once a tube is filled, the next key step is to seal. A weak seal may result in leaks, affect hygiene, or reduce shelf life. Toothpaste tubes typically use either heat sealing or ultrasonic sealing.

King Pack Solutions provides both:

- Heat Sealing: Best for laminated or plastic tubes. Applies hot air to seal the material.

- Ultrasonic Sealing: No heat needed. Seal with high-frequency vibration is perfect for environmentally friendly tubes or heat-sensitive products.

Sealing performance depends on multiple variables. Temperature, pressure, and dwell time. That is the reason why King Pack machines have adjustable settings and real-time monitoring. Our operators can fine-tune the seal strength based on tube material and paste viscosity.

A Smoother Workflow With Integrated Systems

For greater output and less downtime, complete integration is the solution. Rather than purchasing individual machines for filling, sealing, and capping, most manufacturers opt for King Pack’s combined systems. These configurations coordinate every step so tubes flow without interruption from one station to the next.

The major advantages are:

- Less changeover time

- Less manual setup

- Integrated quality control checkpoints

We can also add induction sealing for tamper protection or automatic capping if your packaging needs it.

Final Thoughts

Toothpaste manufacturing is no longer just about the formula. It’s about how efficiently you can deliver it. Precision filling and secure sealing are no longer optional. They’re essential. And with our wide range of automated, hygiene-focused, and efficient machines, King Pack Solutions helps toothpaste manufacturers stay ahead.

Need more control over your filling and sealing process?

Talk to the team at King Pack Solutions and get expert guidance on what fits your setup best.